In today’s fast-paced automotive landscape, staying ahead is not just about keeping up with the latest trends but leveraging your data. Whether refining production or predicting market demands, how well you manage and utilize your data can set you apart in this highly competitive industry.

This is where powerful tools such as Microsoft Fabric (MS Fabric) come into play. MS Fabric is designed to revolutionize how manufacturers approach data management. It centralizes all data operations into one platform, enabling advanced analytics for deeper insights while providing comprehensive security measures to protect sensitive information. This opens up opportunities for automotive manufacturers to reimagine production processes, make smarter decisions, and maintain a competitive edge.

Key Features of Microsoft Fabric Services for Automotive Manufacturing

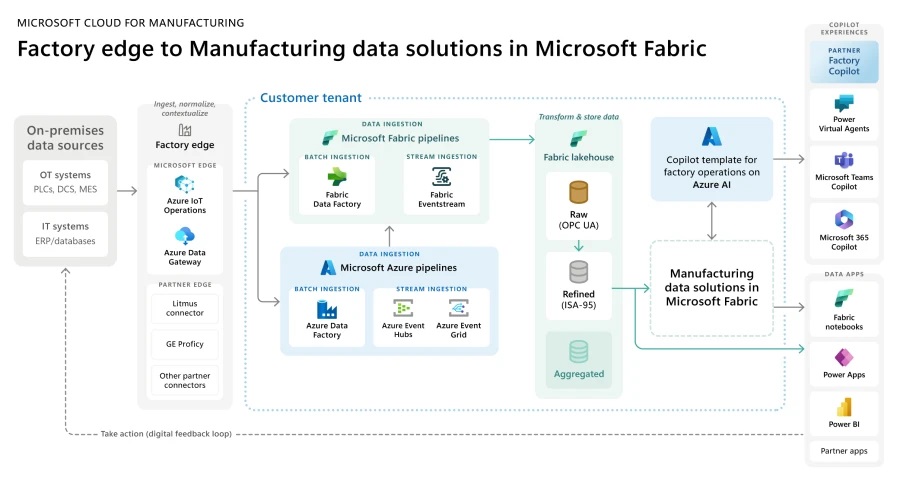

Data Integration and Ingestion – Bringing Data Together

Automotive manufacturing produces massive amounts of data from various sources, and managing it all can be overwhelming. Some of the key data sources include:

- IoT devices on the shop floor — monitor equipment performance, track production rates, and ensure quality control in real time.

- ERP systems — Enterprise Resource Planning (ERP) systems handle everything from inventory management to supply chain operations, ensuring the smooth running of day-to-day business processes.

- PLM software — Product Lifecycle Management (PLM) software tracks every phase of a vehicle’s development, from design to production, ensuring compliance and quality.

While these systems play a crucial role, they often operate in isolation, limiting manufacturers’ ability to view their operations comprehensively. MS Fabric pulls all this data into a unified space, breaking down barriers between systems so manufacturers can get a complete picture of their operations. With the help of integrated data pipelines from Data Factory, businesses can quickly pull in data from various sources and derive valuable insights from it.

Data Governance and Security – Safeguarding Your Information

Compliance and data integrity aren’t just boxes to tick in the automotive industry—they are fundamental to maintaining trust and avoiding costly setbacks. MS Fabric’s data governance tool, Purview, ensures that the proper standards are followed and that data stays secure. Purview goes beyond basic governance by offering deep visibility into the entire lifecycle of your data. This tool tracks where and how data is used and enforces strict controls to ensure that only the right people have access to sensitive information.

For automotive companies dealing with complex regulatory requirements, this means less time worrying about audits and more time focusing on innovation. By minimizing the risks of breaches and mismanagement, Purview doesn’t just protect your data—it strengthens your entire operation, ensuring you stay compliant while maximizing efficiency and security at every level.

Advanced Analytics and AI – Unlocking Valuable Insights

MS Fabric shines when it comes to predictions and insights. Synapse Analytics provides real-time visibility into production lines, equipment, and supply chains. These insights help with everything from scheduling preventive maintenance to catching potential quality issues before they become a problem. AI-powered models can also track defects during manufacturing, reducing the chances of costly reworks or recalls. By building AI into daily operations, MS Fabric helps manufacturers run more smoothly and proactively.

Real-time Insights and Reporting – Empowering Instant Decisions

With MS Fabric, decision-makers in the automotive industry gain access to up-to-the-minute insights through Power BI’s visual dashboards and reporting tools. Whether managers monitor production output, track downtime, or assess the supply chain, leadership can act quickly and confidently. With real-time data at their fingertips, they can respond to challenges faster, making their operations more agile and responsive.

Real-World Automotive Manufacturing Scenarios

It is worth exploring some practical examples of how MS Fabric can address specific challenges in the automotive industry:

Scenario 1: Connected Vehicle Data and Services

The problem: Modern vehicles generate vast amounts of data through sensors, onboard systems, and connectivity features. However, many manufacturers struggle to turn this data deluge into actionable insights that enhance products and services.

Impact: Not using connected vehicle data effectively is a huge missed opportunity. Manufacturers could improve vehicle performance, offer predictive maintenance, or deliver personalized in-car experiences. Failing to do so limits customer satisfaction and leaves brands behind in a highly competitive market.

How Fabric helps: Microsoft Fabric simplifies how manufacturers manage and analyze massive amounts of vehicle data. It streams real-time data, capturing everything from telemetry to sensor readings. With built-in AI-driven analytics, manufacturers gain a clear view of how customers are actually using their vehicles, spotting usage trends and performance issues and predicting maintenance needs.

Companies can offer more innovative services, such as remote diagnostics and over-the-air software updates, turning data into value. Fabric even enables personalized in-vehicle experiences, tailoring infotainment, navigation, and other features to the driver’s preferences. Not only does this boost customer satisfaction, but it also provides manufacturers with valuable feedback for future vehicle designs.

Scenario 2: Production Line Optimization

Image Credit – Microsoft

The problem: Automotive production lines are complex systems where minor inefficiencies can lead to significant delays and increased costs. Manual interventions, bottlenecks, and underperforming machines reduce overall productivity and throughput.

Impact: Reduced production efficiency leads to higher per-unit production costs, delays in vehicle delivery, and a drop in overall profitability. Manufacturers struggle to maintain consistent output while keeping operational costs down.

How Fabric helps: Microsoft Fabric’s data integration and real-time monitoring capabilities allow manufacturers to track the performance of every machine and process on the production line. By leveraging AI-powered analytics, manufacturers can identify bottlenecks and underperforming machines and recommend adjustments to machine speeds, staffing levels, or shift schedules. Automated alerts and dashboards provide real-time visibility into production performance, allowing plant managers to react quickly to any inefficiencies. Fabric’s process mining tools further analyze workflow data, helping identify patterns that could be optimized for increased efficiency.

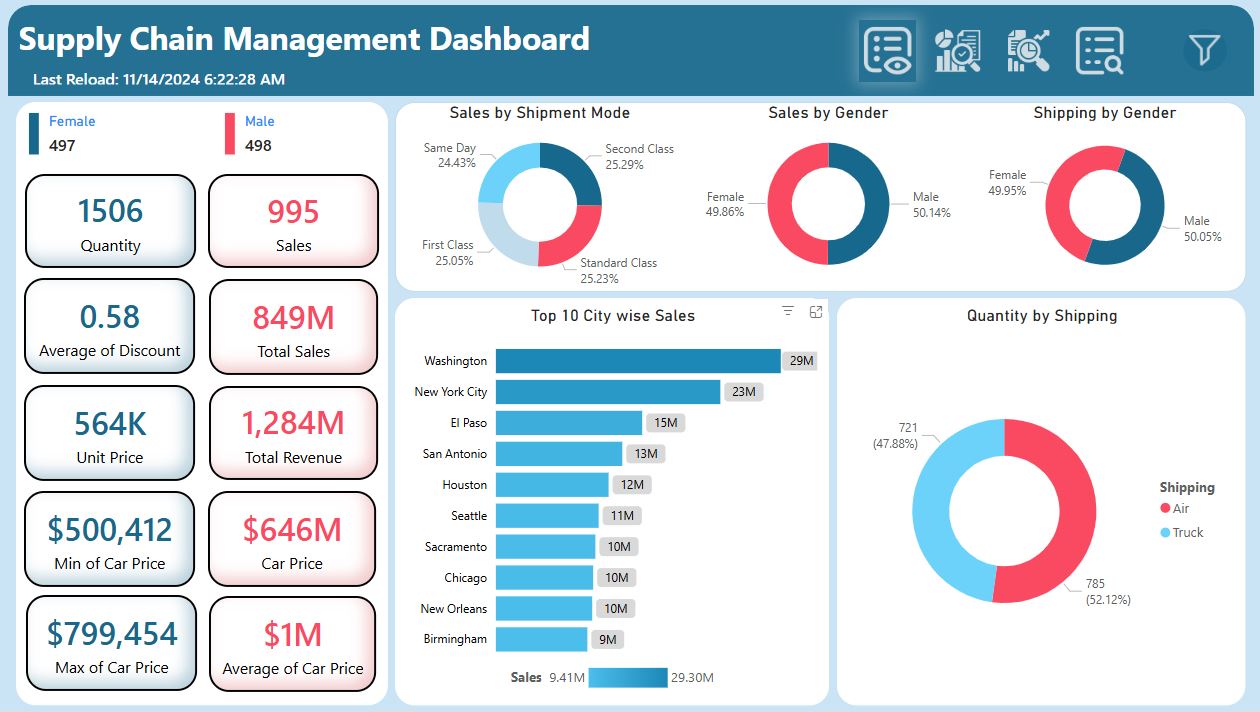

Scenario 3: Supply Chain Optimization

Image Credit – Microsoft

The problem: Automotive manufacturers rely on complex, global supply chains to source parts and components. Managing inventory, transportation, and logistics across multiple suppliers and regions can lead to inefficiencies such as overstocking, delays, and increased costs.

Impact: Supply chain disruptions can delay production, increase storage costs, and result in parts shortages, which ultimately affect vehicle delivery times. In a competitive market, manufacturers that cannot optimize their supply chain risk losing market share to more agile competitors.

How Fabric helps: Microsoft Fabric provides real-time visibility across the entire supply chain, from suppliers to manufacturing plants and distributors. Fabric helps manufacturers anticipate demand fluctuations and adjust inventory levels by analyzing inventory levels, transportation routes, and logistics. It also identifies inefficiencies in transportation routes, optimizes delivery times, and reduces fuel consumption. Fabric’s insights allow manufacturers to reduce waste, lower storage costs, and improve overall supply chain coordination, ensuring that parts are available when and where needed.

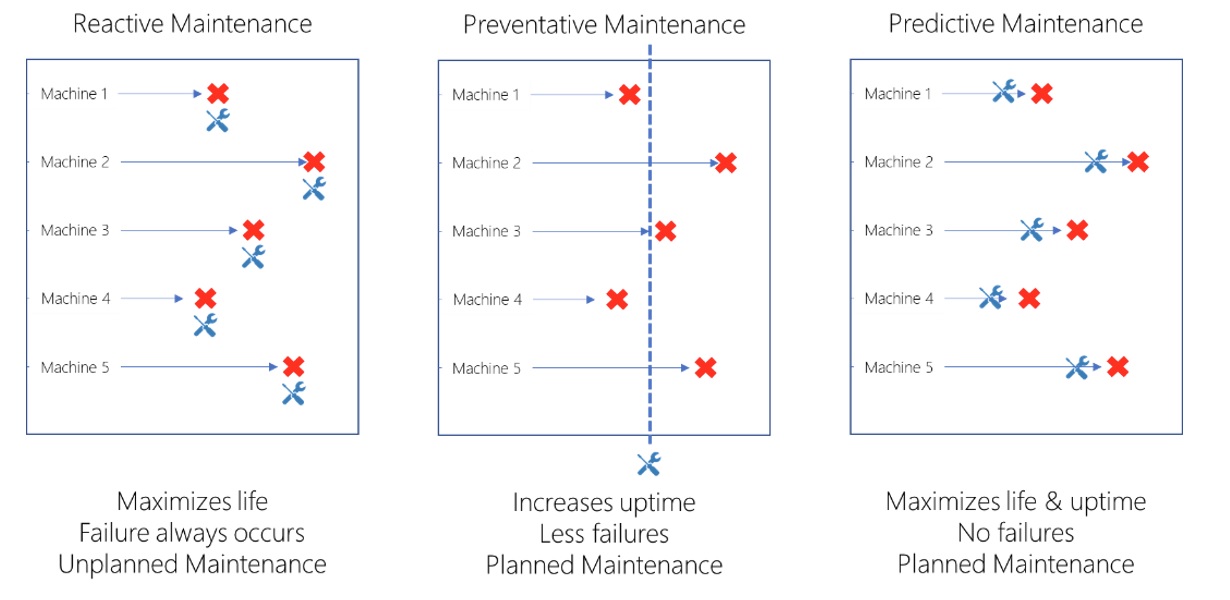

Scenario 4: Predictive Maintenance

Image Credit – Microsoft

The problem: In automotive manufacturing, machine failures and unplanned downtime disrupt production schedules, leading to increased costs and missed deadlines. Traditional maintenance strategies, either reactive or based on set schedules, often fail to address issues before they escalate.

Impact: Every minute of downtime can result in financial losses, delayed vehicle production, and missed delivery deadlines. Manufacturers also face higher operational costs from emergency repairs and the need for replacement parts. Over time, this can affect production efficiency, profitability, and the company’s competitive edge.

How Fabric helps: Microsoft Fabric integrates IoT devices that monitor machinery health in real time, tracking data such as temperature, vibration, and pressure. This data feeds into the Fabric platform, where AI algorithms analyze it to predict potential failures. Manufacturers can schedule repairs or replacements in advance by forecasting when equipment is likely to malfunction, minimizing unplanned downtime. The result is improved machine reliability, optimized maintenance schedules, and significant cost savings in the long run. Fabric helps turn maintenance from a reactive task into a proactive strategy that keeps operations running smoothly.

Scenario 5: Customization and Personalization of Vehicles

The problem: The demand for customized and personalized vehicles is increasing. Meeting these demands can disrupt production lines traditionally designed for mass production, leading to longer lead times and higher costs.

Impact: Without an efficient process to handle customization, manufacturers face longer delivery times, higher production costs, and reduced customer satisfaction. Customization can also lead to inefficiencies in inventory management and production scheduling.

How Fabric helps: Microsoft Fabric facilitates mass customization by leveraging data analytics, AI, and supply chain coordination. Fabric allows manufacturers to create a flexible production environment that adjusts to individual customer specifications without sacrificing efficiency. Using real-time data from customer orders and preferences, Fabric integrates with the production line to ensure that the correct components are available at the right time. AI algorithms can optimize production schedules to ensure customized orders are processed without disrupting the flow of standard vehicles. Fabric also helps track the supply chain to ensure that custom parts are available on demand. By optimizing production and supply, Fabric allows manufacturers to meet customer customization demands without causing delays or increasing costs.

Benefits of Microsoft Fabric Services for Automotive Manufacturing

- By automating data integration, enhancing real-time decision-making, and supporting predictive analytics, MS Fabric allows manufacturers to optimize operations. Reducing production delays, minimizing downtime, and streamlining supply chains contribute to lower costs and increased productivity.

- Real-time insights are a game-changer for automotive manufacturers. Leaders can make data-driven decisions immediately impacting operations, from predicting market trends to optimizing production lines. The ability to quickly adapt to changing conditions helps manufacturers remain agile and responsive.

- By integrating AI-powered analytics, manufacturers can catch defects early and ensure product quality remains high. This leads to fewer recalls and customer complaints, improving brand reputation and reducing costs related to rework.

- MS Fabric empowers manufacturers with the agility to innovate quickly and stay ahead of market demands. By transforming data into actionable insights, manufacturers can refine their processes, accelerate product development, and remain competitive in an evolving industry.

Final Word

Our Microsoft Fabric consulting services enable automotive manufacturers to tackle complex industry challenges by leveraging real-time data, advanced analytics, and AI-driven insights. Whether improving maintenance strategies, enhancing quality control, or ensuring compliance, Fabric equips manufacturers with the tools they need to optimize operations and stay competitive in a rapidly evolving market. With its ability to boost efficiency, enhance product quality, and maintain regulatory compliance, Microsoft Fabric positions automotive manufacturers to lead in an increasingly data-driven world.

Ready to explore how Microsoft Fabric could transform your manufacturing operations? Reach out for a demo of today and see the impact first-hand.