The manufacturing landscape is undergoing a revolution driven by Industrial IoT (IIoT) and interconnected machines. While this connectivity promises increased efficiency, automation, and real-time data collection, it also creates a new vulnerability: cybersecurity.

According to a Forbes report on cybersecurity forecasts and market estimates, the global cybersecurity market, which was $173 billion in 2020, is estimated to rise to $270 billion by 2026, with a growing preference for outsourced managed security services. This surge reflects the rising threats faced by manufacturers.

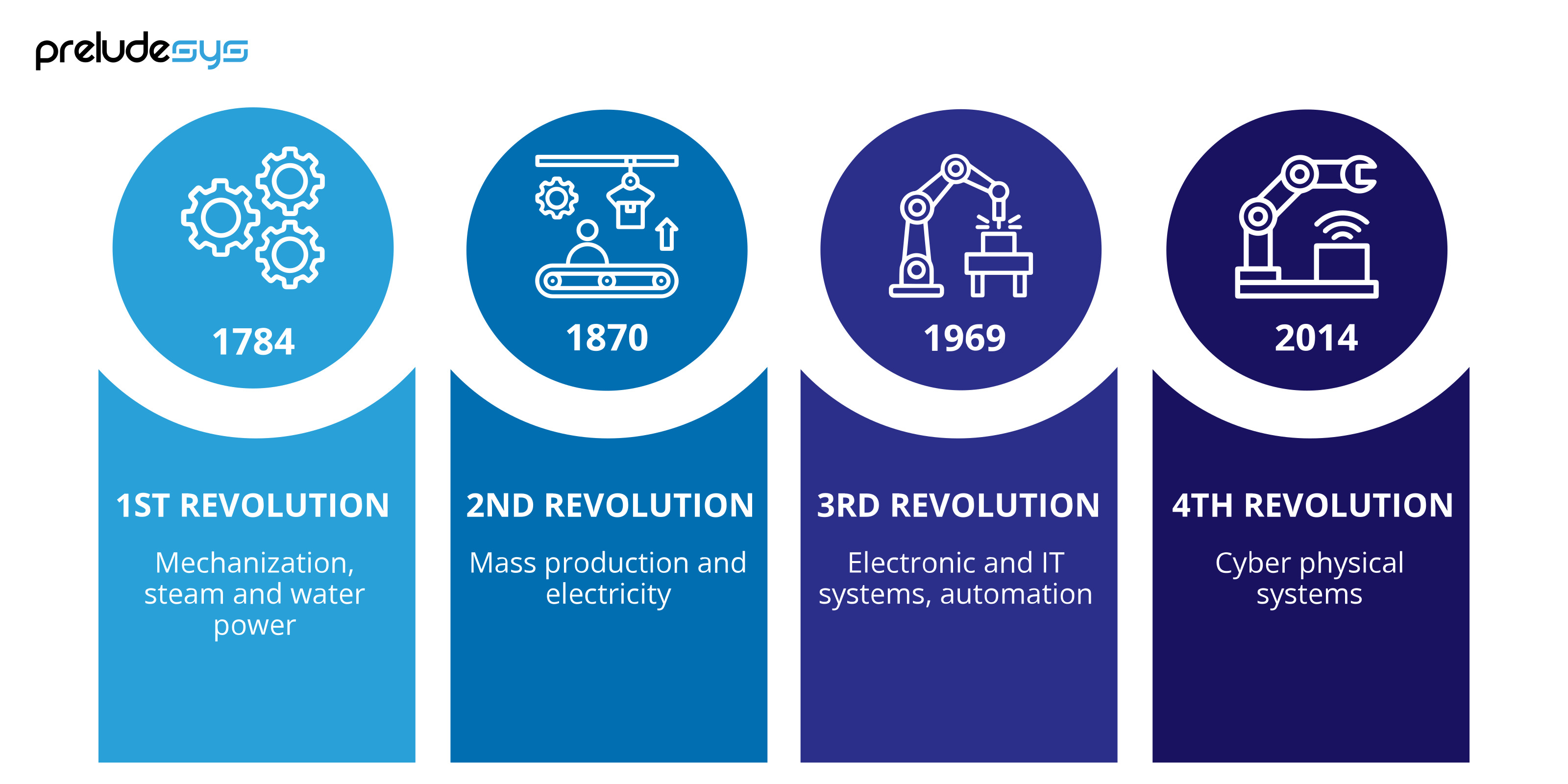

In this blog post, we will explore the importance of cybersecurity in today’s manufacturing environment and discover the growing threats, the potential consequences of a cyberattack, and, most importantly, the steps you can take to secure your manufacturing ecosystem. We will also highlight the changes brought in the manufacturing space with the advent of the industry 4.0 revolution and how your enterprise can safeguard its plants from cyberattacks and equip itself to adapt to the changing market.

Why Cybersecurity Matters in Manufacturing

Manufacturing facilities are increasingly reliant on connected devices and systems. These include:

- Industrial control systems (ICS): They manage critical infrastructure such as robots and assembly lines.

- Supervisory control and data acquisition (SCADA): Devices that monitor and control industrial processes.

- Internet of Things (IoT) devices: Sensors and actuators collect and transmit real-time data.

These interconnected systems create a complex attack surface for cybercriminals.

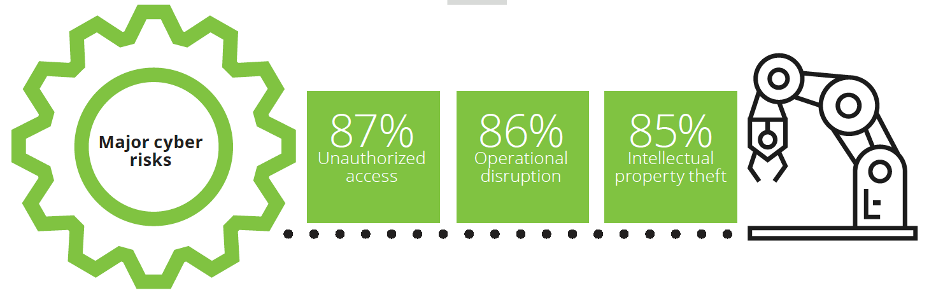

The 2019 Deloitte and MAPI Smart Factory Study conducted by Deloitte and the Manufacturer’s Alliance for Productivity and Innovation (MAPI) found that 40% of the manufacturers surveyed had operations affected by a cyber-incident within 12 months.

Figure: Stats from the 2019 Deloitte and MAPI Smart Factory Study

An unmonitored data breach attack could have devastating consequences, including:

- Production disruptions: Cyberattacks can disrupt manufacturing operations and halt production lines, causing operational downtime and delays that can lead to significant financial losses.

- Data breaches: Sensitive data, such as intellectual property or customer information, could be stolen.

- Reputation Damage: A cybersecurity breach can tarnish a manufacturer’s reputation, losing customers and business partners.

- Safety hazards: Attacks on safety systems could put workers and equipment at risk.

- Legal Liabilities: Cyber threats can expose manufacturers to legal actions and liabilities from affected parties. Regulatory authorities may impose fines and penalties for non-compliance, which can be financially taxing.

The Growing Threat Landscape and Challenges faced by Manufacturers

With the Industry 4.0 revolution, the manufacturing sector faces a growing wave of cyberattacks. This threat surge pushes the industry to prioritize cybersecurity investments. Threats include increasingly sophisticated cyber tools, ransomware attacks encrypting data for ransom, and supply chain vulnerabilities exploited by hackers to access manufacturer networks, leading to revenue losses and reputational damage.

Securing Your Manufacturing Ecosystem

You can reduce risks from evolving cyber threats through precautionary measures and effective strategies.

Some of the top Cybersecurity Regulations and Standards are:

- NIST Cybersecurity Framework: Trusted guidelines for bolstering cybersecurity.

- ISO 27001: Global standard for robust information security management systems.

- Industry-Specific Guidelines: Tailored regulations for different manufacturing sectors (GDPR, CCPA, and NIST).

Additionally, you can also incorporate the following best practices to mitigate these risks and secure your manufacturing ecosystem:

- Conduct regular security assessments: Identify vulnerabilities in your systems and implement measures to address them. Implementing a zero-trust approach can ensure that every user and device is verified and authorized before accessing critical systems. This approach eliminates trust assumptions and requires continuous authentication and authorization throughout the network.

- Invest in Supply Chain Resilience: Cybersecurity compliance helps safeguard the supply chain, reducing the risk of disruptions due to cyberattacks on suppliers or partners.

- Implement strong access controls and endpoint security: Restrict system access only to authorized personnel and use multi-factor authentication. Endpoint security is crucial for protecting systems from malware and unauthorized access.

- Update software and firmware regularly: Regularly updating and patching systems is essential for addressing vulnerabilities and protecting against known exploits. Manufacturers should establish a systematic process for identifying, testing, and deploying updates across their IT and OT networks.

- Educate your employees: Train your workforce on cybersecurity best practices, such as phishing awareness. Regular security awareness training for employees is crucial for creating a security-conscious culture.

- Develop a cyber-incident response plan: Have a plan to respond to a cyberattack quickly. and effectively.

- Segment your network: Isolate critical systems from non-critical ones to limit the impact of a breach.

What to look out for in Industry 4.0?

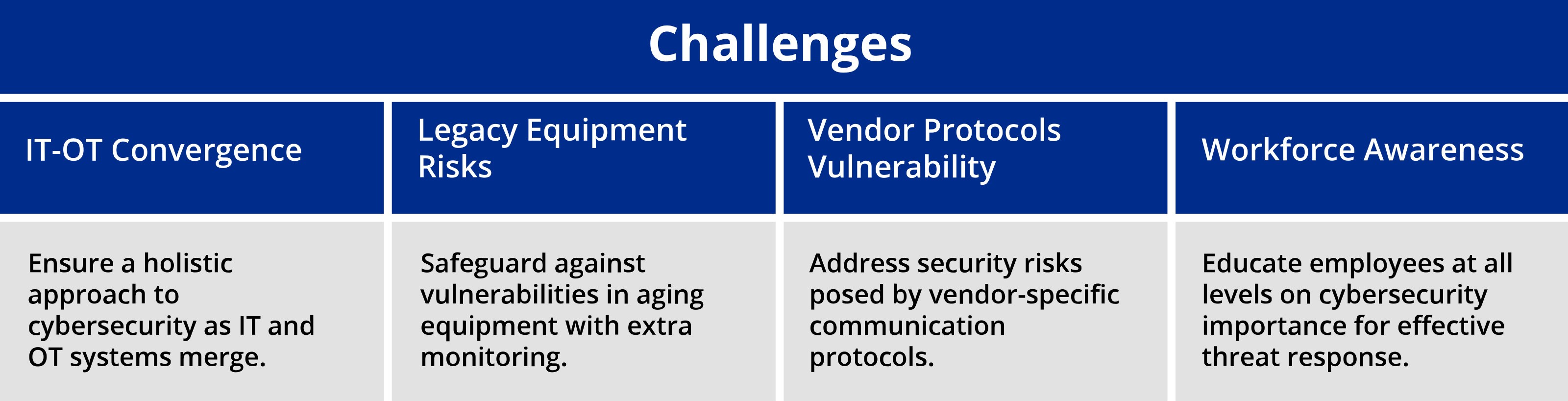

Revolutionizing the manufacturing industry with Industry 4.0 technology is driving a need for a new approach to cybersecurity. As devices become more interconnected, the risk of cyberattacks grows. While Industry 4.0 brings operational benefits, it also poses cybersecurity challenges, such as monitoring device inventories and detecting unusual activity.

To combat these threats, manufacturers must prioritize developing robust OT cybersecurity strategies by integrating OT and IT security efforts, creating specific plans, and treating cybersecurity as essential. Collaboration with organizations shaping regulations is critical to staying ahead in this rapidly changing landscape. In the age of Industry 4.0, proactive and comprehensive cybersecurity measures are no longer optional; they’re crucial for success.

Why Choose PreludeSys

PreludeSys understands the evolving challenges faced by the manufacturing industry and offers tailored digital service solutions to fortify your defenses against modern cyber threats.

- Industry Expertise: With years of experience in manufacturing cybersecurity, we understand your sector’s unique challenges.

- Tailored Solutions: Our services are not one-size-fits-all; we customize our offerings to meet your needs.

- Proven Track Record: Our expertise has a track record of empowering manufacturing industries with resilient cybersecurity frameworks.

As a strategic Delphix and Microsoft partner, our cybersecurity implementation services will analyze your manufacturing ecosystem to identify and comprehend potential cyber risks. By crafting customized strategies, we ensure your operations are shielded against vulnerabilities unique to your industry.

To delve deeper into how our integration of cybersecurity and data protection strategies can transform your approach to safeguarding critical information. Check out our recent blog on Reimagining Data Compliance and Data Protection with Delphix.

Leverage our expertise as your trusted cybersecurity partner. Talk to our experts today!